F14 plywood is a versatile and practical choice for formwork applications. It offers a range of benefits that make it an excellent option for construction projects. In this article, we will delve into the basics of F14 plywood, its composition, key features, and its role in formwork applications. We will also compare F14 plywood to other materials, discuss its advantages, and explore potential challenges and solutions when using it. By the end of this article, you will have a comprehensive understanding of why F14 plywood is the ideal choice for formwork applications.

Understanding the Basics of F14 Plywood

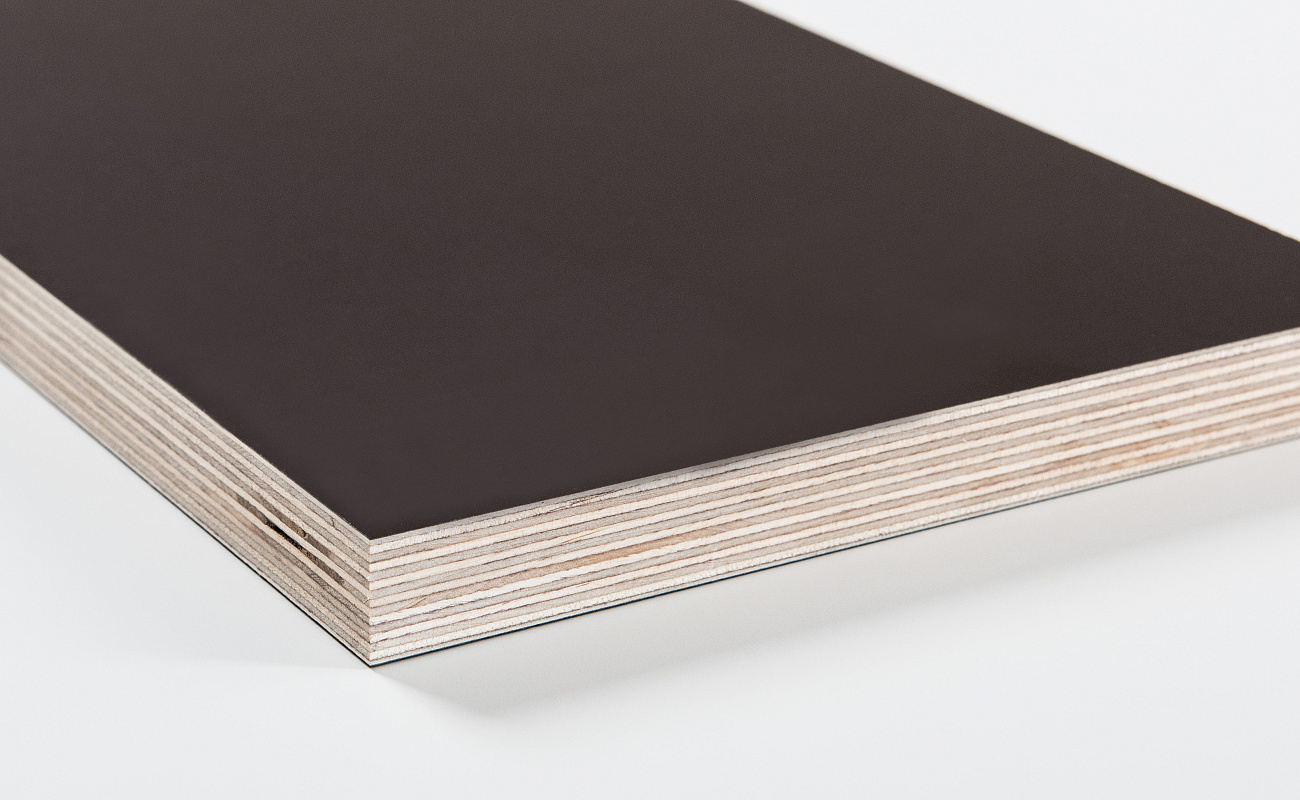

F14 plywood is a type of structural plywood that is specifically engineered for formwork applications. It is known for its exceptional strength and durability, making it highly suitable for construction projects that require sturdy and reliable formwork. Made from layers of wood veneers glued together with a waterproof adhesive, F14 plywood is designed to withstand the rigors of formwork while providing a smooth and consistent surface. Its solid construction and dimensional stability make it an excellent choice for various formwork applications.

The Composition of F14 Plywood

F14 plywood is typically composed of multiple layers of softwood veneers. These veneers are arranged in a cross-grain pattern, with each layer perpendicular to the adjacent layer. This construction method, known as cross-banding, enhances the strength and stability of the plywood. The layers are bonded together using a high-quality adhesive that ensures the integrity and durability of the plywood. Additionally, F14 plywood is often treated with preservatives to protect it against fungal decay and termite attack.

Key Features of F14 Plywood

One of the key features that sets F14 plywood apart is its high-strength rating. It is able to support heavy loads and withstand the pressure exerted by wet concrete during the formwork process. This strength is a result of the plywood’s construction and the quality of the materials used. F14 plywood also offers excellent resistance to moisture and humidity, preventing warping or delamination that can compromise its structural integrity. Additionally, F14 plywood has a smooth surface finish that allows for easy release of formwork and provides a consistent finish to concrete.

Another notable feature of F14 plywood is its versatility. It can be used for a wide range of formwork applications, including walls, columns, beams, and slabs. Its strength and durability make it suitable for both residential and commercial construction projects. Whether you’re building a small house or a large commercial building, F14 plywood can provide the necessary support and stability for your formwork needs.

In addition to its practical benefits, F14 plywood is also an environmentally friendly choice. It is made from sustainably sourced wood, ensuring that forests are managed responsibly. The manufacturing process of F14 plywood also minimizes waste and reduces the carbon footprint, making it a sustainable option for construction projects.

The Role of Plywood in Formwork Applications

Plywood plays a crucial role in formwork applications, providing the necessary support and structure for the casting of concrete. It acts as a temporary mold, shaping the concrete into the desired form while it sets and hardens. The use of plywood in formwork offers several advantages, including cost-effectiveness, versatility, ease of use, and the ability to achieve complex shapes and finishes.

Read about f17 at: Exploring the Versatility of F17 Grade Plywood in Construction

The Importance of Material Choice in Formwork

Choosing the right material for formwork is essential to the success of a construction project. The material must possess the necessary strength and durability to withstand the forces exerted by the concrete and any external factors. F14 plywood, with its high-strength rating and dimensional stability, is an ideal choice for formwork applications. It provides the necessary support and ensures the integrity of the concrete structure during the construction process.

How Plywood Contributes to Formwork Success

Plywood contributes to the success of formwork applications in multiple ways. Its smooth surface finish allows for easy release of formwork, reducing the risk of damage to the concrete. The dimensional stability of plywood ensures that the formwork retains its shape and size throughout the construction process. Plywood is also versatile, allowing for the creation of various formwork configurations to meet specific project requirements. Additionally, the lightweight nature of plywood makes it easy to handle and transport, improving efficiency on the construction site. Learn more about versatile on https://versatileeducation.org/

Furthermore, plywood offers excellent resistance to moisture, making it suitable for formwork applications in both indoor and outdoor settings. This moisture resistance helps prevent warping and swelling, ensuring the accuracy and stability of the formwork. Plywood’s ability to withstand the rigors of the construction environment, including exposure to harsh weather conditions, further enhances its durability and reliability.

In addition to its functional benefits, plywood also provides aesthetic advantages in formwork applications. Its smooth surface finish allows for the creation of high-quality concrete finishes, enhancing the visual appeal of the final structure. Whether it’s a sleek and modern design or a more rustic and textured look, plywood can help achieve the desired aesthetic outcome.

Moreover, plywood is an environmentally friendly choice for formwork applications. It is a renewable resource, with many plywood manufacturers adhering to sustainable forestry practices. By choosing plywood for formwork, construction projects can contribute to the preservation of forests and reduce the carbon footprint associated with building materials.

Comparing F14 Plywood to Other Materials

When selecting materials for formwork applications, it is important to evaluate and compare their properties and suitability for the project at hand. Let’s take a closer look at how F14 plywood compares to traditional wood and metal in formwork applications.

Formwork is a crucial component in construction projects, providing the necessary support for freshly poured concrete to take shape and harden into a solid structure. The choice of formwork material can significantly impact the quality, efficiency, and cost-effectiveness of the construction process.

F14 Plywood Vs. Traditional Wood

Traditional wood, such as solid timber, has long been used in formwork applications. While wood offers certain advantages, such as natural aesthetics and ease of availability, it is prone to warping, swelling, and decay when exposed to moisture. F14 plywood, on the other hand, offers superior dimensional stability, strength, and resistance to moisture. It provides a consistent and reliable choice for formwork applications, solving the challenges associated with traditional wood.

Furthermore, F14 plywood is manufactured to precise standards, ensuring uniform thickness and strength properties across the entire sheet. This consistency is essential in formwork applications to maintain the structural integrity of the concrete during the pouring and curing stages. The smooth surface of F14 plywood also facilitates easy release from the concrete once it has set, reducing the risk of surface blemishes and imperfections. To read more about integrity click here.

F14 Plywood Vs. Metal in Formwork Applications

Metal is another alternative to consider when choosing materials for formwork applications. Metal formwork systems offer excellent strength and durability. However, metal formwork can be costly, heavy, and less flexible compared to F14 plywood. F14 plywood provides a lightweight and cost-effective solution without compromising on strength and performance. It allows for easy customization and modification to suit the specific formwork requirements of each project.

Moreover, the flexibility of F14 plywood allows for intricate formwork designs and shapes to be easily achieved, catering to the unique architectural requirements of modern construction projects. Its versatility extends to various surface finishes, from smooth to textured, providing options for different concrete surface appearances. The affordability and recyclability of F14 plywood further contribute to its appeal as a sustainable choice for formwork applications, aligning with the growing emphasis on environmentally friendly construction practices.

The Advantages of Using F14 Plywood in Formwork

The use of F14 plywood in formwork applications brings several advantages to construction projects. Let’s explore some of the key benefits that make F14 plywood the preferred choice for formwork.

When it comes to construction projects, durability and strength are crucial factors to consider. F14 plywood is renowned for its exceptional durability and strength. Its solid construction, high-strength rating, and resistance to moisture ensure that the formwork remains intact and stable throughout the construction process. This durability allows for multiple uses of F14 plywood, reducing the need for frequent replacement and increasing cost-effectiveness.

Moreover, in addition to its durability, F14 plywood offers excellent value for money. Compared to alternative materials, such as metal formwork, F14 plywood is more cost-effective, making it a budget-friendly choice for formwork applications. Its lightweight nature also reduces transportation costs and improves efficiency on the construction site.

Durability and Strength of F14 Plywood

F14 plywood is renowned for its exceptional durability and strength. Its solid construction, high-strength rating, and resistance to moisture ensure that the formwork remains intact and stable throughout the construction process. This durability allows for multiple uses of F14 plywood, reducing the need for frequent replacement and increasing cost-effectiveness.

Cost-effectiveness of F14 Plywood

F14 plywood offers excellent value for money. Compared to alternative materials, such as metal formwork, F14 plywood is more cost-effective, making it a budget-friendly choice for formwork applications. Its lightweight nature also reduces transportation costs and improves efficiency on the construction site.

Environmental Impact of Using F14 Plywood

Environmental sustainability is a growing concern in the construction industry. F14 plywood is an environmentally friendly choice for formwork applications. It is made from sustainable timber sources and can be recycled or repurposed at the end of its lifespan. Additionally, the use of F14 plywood reduces reliance on metal, which often requires energy-intensive production processes.

Potential Challenges and Solutions When Using F14 Plywood

While F14 plywood offers numerous advantages for formwork applications, it is important to be aware of potential challenges that may arise and how to address them effectively.

Overcoming Common Issues with F14 Plywood

One common issue with F14 plywood is the risk of surface damage during handling and construction. To minimize this risk, proper handling techniques and the use of protective measures, such as edge protectors, should be employed. It is also essential to ensure that the plywood is stored appropriately to prevent moisture absorption and potential damage to its structural properties.

Ensuring Quality and Safety with F14 Plywood

To ensure the quality and safety of F14 plywood in formwork applications, it is imperative to source the plywood from reputable suppliers who adhere to industry standards and quality control measures. Regular inspections and maintenance of the formwork are essential to identify any signs of damage or wear and to address them promptly. Adhering to proper construction practices and guidelines will help mitigate potential risks and ensure the successful use of F14 plywood in formwork.

Conclusion

In conclusion, F14 plywood is the ideal choice for formwork applications due to its exceptional strength, durability, and dimensional stability. Its composition, key features, and suitability for formwork make it a reliable and efficient material for construction projects. When compared to traditional wood and metal, F14 plywood offers distinct advantages in terms of cost-effectiveness, ease of use, and environmental impact. Proper handling, storage, and adherence to construction guidelines are essential in overcoming potential challenges and ensuring the successful use of F14 plywood in formwork. By choosing F14 plywood for formwork applications, construction professionals can optimize their projects by achieving the desired quality, efficiency, and sustainability.