F17 grade plywood is a type of plywood that is widely used in the construction industry due to its exceptional strength and durability. In this article, we will delve into the basics of F17 grade plywood, its role in construction, the advantages it offers, and its comparison to other construction materials. We will also discuss the safety and environmental impact of using F17 grade plywood. By understanding the various aspects of this versatile material, builders and homeowners can make informed decisions regarding its use in their projects.

Understanding the Basics of F17 Grade Plywood

Before exploring its applications and benefits, let’s take a closer look at what F17 grade plywood is and its key characteristics.

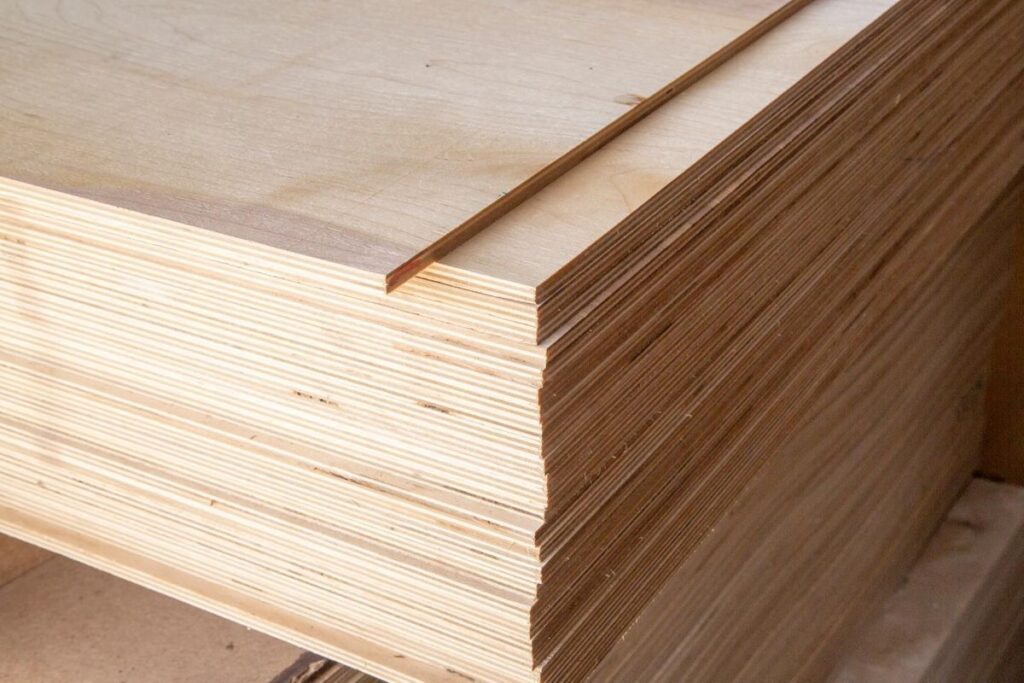

F17 grade plywood is a type of engineered wood panel that is made by gluing together several thin layers of wood veneer. Each layer, or ply, is oriented at right angles to the adjacent layers, providing strength and stability to the finished product. The “F17” designation refers to the plywood’s structural rating, indicating its ability to withstand a certain amount of stress and load.

Definition and Key Characteristics

F17 grade plywood is commonly used in construction and structural applications where strength and durability are paramount. Its high structural rating makes it suitable for use in beams, bracing, and other load-bearing components. Additionally, the cross-laminated construction of F17 plywood enhances its resistance to warping, twisting, and cracking, making it a reliable choice for projects requiring long-term stability.

Manufacturing Process of F17 Plywood

The manufacturing process of F17 grade plywood involves several steps. It starts with sourcing high-quality hardwood or softwood logs, which are then de-barked and cut into veneers. These veneers are then dried to reduce their moisture content and improve dimensional stability.

Next, the veneers go through a process called cross-laminating, where they are glued together with an adhesive, such as phenol formaldehyde resin, and pressed under high pressure. The resulting plywood panels are trimmed to size, sanded, and inspected for quality before being shipped to construction sites.

Quality control is a critical aspect of F17 plywood production to ensure that the panels meet the required standards for strength and performance. Manufacturers conduct rigorous testing procedures to assess factors such as glue bond strength, panel thickness, and dimensional accuracy. This attention to detail helps maintain the reputation of F17 grade plywood as a reliable and consistent building material in the construction industry.

The Role of F17 Grade Plywood in Construction

Due to its strength and versatility, F17 grade plywood is used in various construction applications, both structural and non-structural.

F17 grade plywood is manufactured using high-quality hardwood veneers bonded together with a waterproof adhesive, resulting in a durable and reliable material. Its F17 rating signifies that it can withstand high levels of stress and is suitable for use in demanding construction projects.

To read about f14 plywood click here.

Structural Applications of F17 Plywood

F17 grade plywood finds wide usage in structural applications such as roofing, flooring, wall sheathing, and formwork. It provides excellent stability and load-bearing capacity, making it an ideal choice for building structures that need to withstand heavy loads and adverse weather conditions.

When used in roofing applications, F17 grade plywood acts as a sturdy base for roofing materials, ensuring a secure and long-lasting roof structure. In flooring, it offers a smooth and level surface for various floor finishes to be applied, enhancing the overall aesthetics of the space.

Non-Structural Applications of F17 Plywood

Besides its structural applications, F17 grade plywood is also used in non-structural applications. It is commonly employed in furniture making, cabinetry, interior finishes, and decorative purposes. The aesthetic appeal and versatility of F17 grade plywood make it a preferred choice for creating beautiful and functional spaces.

In furniture making, F17 grade plywood’s strength and dimensional stability make it an ideal material for crafting durable and long-lasting pieces. Its smooth surface finish allows for easy painting, staining, or laminating to achieve the desired look for cabinetry and interior finishes. Additionally, its consistent quality and resistance to warping make it a reliable option for decorative purposes, adding a touch of elegance to any design. Find more about resistance at https://micro.magnet.fsu.edu/electromag/electricity/resistance.html

Advantages of Using F17 Grade Plywood in Construction

There are numerous advantages associated with using F17 grade plywood in construction projects. Let’s explore some of the key benefits it offers.

Durability and Strength

F17 grade plywood is known for its exceptional durability and strength. Its cross-laminated structure provides enhanced strength and resistance to warping, shrinking, and swelling. This makes it an ideal choice for applications that require long-lasting and robust construction materials.

Versatility and Adaptability

Another significant advantage of F17 grade plywood is its versatility and adaptability. It can be easily cut, shaped, and joined using common woodworking tools and techniques. This enables builders and designers to create customized solutions for their specific construction needs.

Moreover, F17 grade plywood is also highly resistant to moisture and humidity, making it suitable for use in environments where other materials may degrade or weaken over time. This moisture resistance helps prevent mold, mildew, and rot, ensuring the structural integrity of the construction project for years to come.

Additionally, F17 grade plywood is environmentally friendly as it is often sourced from sustainably managed forests. This sustainable sourcing not only reduces the environmental impact of construction projects but also promotes responsible forestry practices. By choosing F17 grade plywood, builders can contribute to the preservation of forests and natural habitats.

Comparing F17 Grade Plywood with Other Construction Materials

When considering construction materials, it is important to evaluate their pros and cons. Let’s compare F17 grade plywood with other commonly used materials.

Construction projects require careful consideration of materials to ensure durability and structural integrity. F17 grade plywood, known for its strength and reliability, is a popular choice among builders and contractors. Its composition of multiple layers of wood veneer bonded together with strong adhesives results in a sturdy and dimensionally stable product.

F17 Plywood vs. Traditional Wood

Compared to traditional wood, F17 grade plywood offers several advantages. It is more uniform in strength and quality, as it is manufactured under controlled conditions. Additionally, plywood panels are less prone to splitting, warping, and shrinking, ensuring better long-term performance.

Traditional wood, while versatile, can vary in quality and strength depending on the species and growth conditions. In contrast, F17 grade plywood provides consistent strength properties across the entire sheet, making it a reliable choice for structural applications.

F17 Plywood vs. Other Plywood Grades

Within the plywood family, F17 grade plywood stands out due to its higher structural rating. It is designed to withstand heavier loads compared to lower grade plywood, making it suitable for demanding construction applications.

Lower grade plywood may lack the strength and durability required for projects that involve significant weight-bearing or structural demands. F17 grade plywood’s enhanced load-bearing capacity and resistance to bending make it an ideal choice for applications where strength and stability are paramount. Click here to read more about stability.

Safety and Environmental Impact of F17 Grade Plywood

Ensuring safety and minimizing environmental impact are crucial considerations in construction. Let’s examine the safety measures associated with F17 grade plywood and its environmental implications.

Fire Resistance and Safety Measures

F17 grade plywood, like other plywood grades, is treated with fire-retardant chemicals to enhance its fire resistance properties. This treatment helps to slow down the spread of flames in case of a fire, providing valuable time for evacuation and firefighting efforts. It is crucial for builders and contractors to adhere to fire safety regulations and guidelines when using F17 grade plywood in construction projects. Regular inspections and maintenance routines can also help ensure that the fire resistance properties of the plywood are maintained over time.

Sustainability and Environmental Considerations

F17 grade plywood is considered an environmentally friendly choice in construction. It is made from renewable resources such as wood from sustainably managed forests. The use of plywood helps to reduce the demand for solid wood, as it is engineered by bonding layers of wood veneers together, making efficient use of the timber resources. Furthermore, advancements in plywood manufacturing processes have led to the development of eco-friendly adhesives and techniques that minimize waste and energy consumption during production. This focus on sustainability not only benefits the environment but also contributes to the overall green building practices in the construction industry.

When selecting materials for construction projects, builders and designers often weigh the benefits of different options to ensure the best outcomes. F17 grade plywood stands out for its exceptional strength and durability, making it a preferred choice for structural applications such as beams, columns, and flooring. Its versatility extends to non-structural uses as well, including furniture making and decorative finishes. By understanding the safety measures in place, such as fire resistance treatments, and considering the environmental impact of sourcing and manufacturing processes, construction professionals can make informed decisions that prioritize safety, sustainability, and long-term performance.